Our extensive range of machines allow for part diameters from .008” up to 1.25”. After a full inspection, these pieces will meet all engineering requirements to complete your project.

Our extensive range of machines allow for part diameters from .008” up to 1.25”. After a full inspection, these pieces will meet all engineering requirements to complete your project.

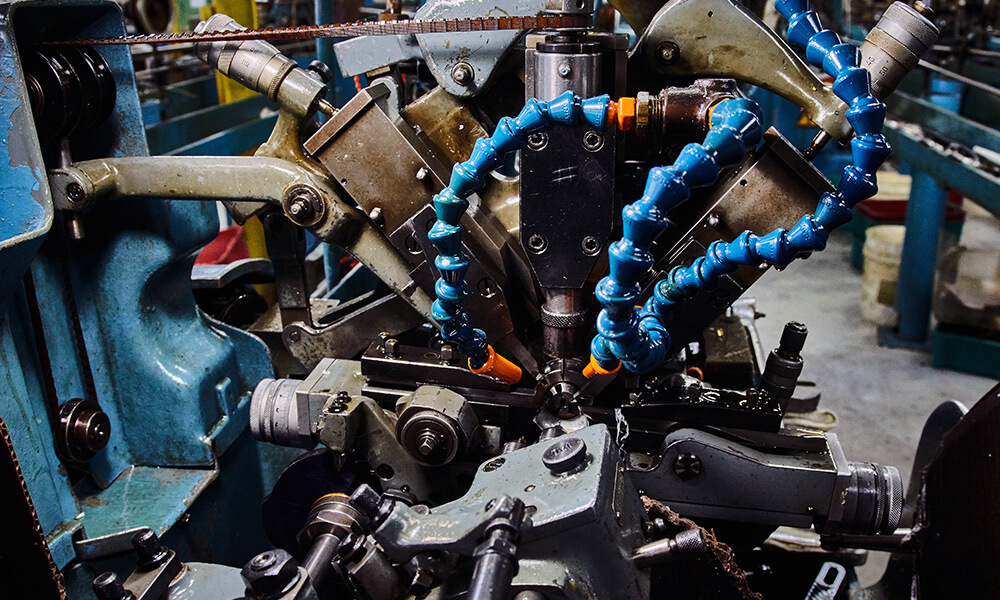

With many machines available, Severna Operations can meet your turn around times and design needs for most projects. Along with these machining services, we also provide CAM design services in-house.

We have a variety of materials for your precision plastics project, such as Teflon®, Fluoroloy H®, and Ultem®. Through swiss screw machining, we also offer a large range of dimensions for your project: from as small as .008” up to 3” in diameter, meeting tolerances as tight as ±.0005″.

After completing production of your components, we use various metrology equipment to fully inspect each part. Depending on the needs of the project, we also offer cryogenic and hand deburring.

Swiss screw machining can take projects that would usually require multiple hours and stops on a 5-axis machine, and machine them in 15 minutes with one operator. When we receive a design, we get to work determining the process for using the machine. Our machinists determine the best way to create the design and meet high tolerances based on the engineering requirements.

These machines allow us to produce a large volume of precision plastic parts quickly and efficiently, so we can meet the demands of any industry.

Max (Cam Screw Machines)

1 in

25.4 mm

Max (CNC Screw Machines)

3 in

76.2 mm

AS 9100 Compliant

ASTM

FDA Compliant

ISO 9001 Certified

Mil-Spec

RoHS Compliant

SAE

Boring

Drilling

External /Internal Thread Cutting

Grinding

Knurling

Milling

Reaming

Slotting

Tapping

Turning