The manufacturing industry is worth about $7 trillion as of this year, 2023. It’s an industry that we couldn’t live without in our world. From engineering buildings and bridges to creating microwaves and appliances that we use on a daily basis, manufacturing is something we can’t forego.

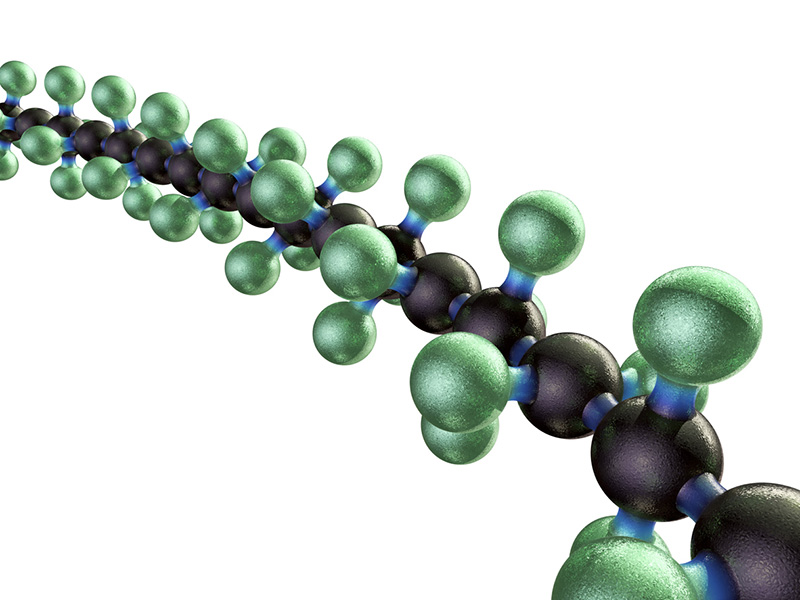

In the manufacturing industry, PTFE, or polytetrafluoroethylene, is one of the most popular materials. It is more commonly known by the brand name Teflon. There are many benefits and uses for PTFE in the industry, such as non-stick coating on kitchen pots and pans as well as medical uses such as test equipment and even implants.

It doesn’t stop there, though. It is also used in the automotive and electrical industries because of the advantages of PTFE.

In simple terms, PTFE is a strong, durable, and nonflammable material that is used in manufacturing. It has a high melting point and a high resistance to many different kinds of chemicals.

The discovery of PTFE changed the entire face of the industry with fluoropolymers because of the advantages of using PTFE.

All fluorocarbons have carbon-fluorine bonds. Their various properties come from this. However, PTFE has a lot of properties that other fluorocarbons do not have.

The only chemicals that can affect polytetrafluoroethylene are highly reactive metals. Here are some of the properties that stand out the most:

There are so many advantages of using PTFE for different applications, especially in manufacturing. Here are a few of the advantages that stand out.

Using a material that is resistant to chemicals is also a huge advantage. This property makes an ideal because it can be used in many different industries such as chemical processing. There is also less of a concern of something happening if chemicals do get on the material; this includes acids, bases, and organic solvents.

PTFE is able to handle extreme temperatures. It can withstand temperatures up to 260°C, which makes it a great material to use in high-temperature applications. It is also great for use in cryogenic applications because of its ability to withstand colder temperatures.

Because the material has the advantage of low friction, it is often used to coat moving parts. This reduces the friction and wear on these parts by using the material of PTFE. This can prolong the lifespan of many different products, which can reduce the cost of production and manufacturing as a whole.

PTFE is biocompatible. This means that it is not toxic to living tissue. Because of this, it is a common material that is used in medical applications, including implantable medical devices. This gives the industry the ability to use PTFE in various applications where other materials may fall short.

PTFE is a material that is able to withstand high voltages. This makes it a great material to use in high-voltage applications as an electrical insulator.

Another great benefit and advantage of PTFE is that it is a highly durable material. It can withstand harsh environments and applications without the wear and tear that other materials may face. It is not only resistant to UV radiation, but it is also resistant to moisture and most chemicals. This makes it a great material to use both indoors and outdoors.

There are so many advantages of PTFE. From its electrical insulation durability to the biocompatibility it offers; it has a wide range of uses.

There are many unique properties that allow it to be this way. This makes it a great material for many different manufacturing purposes as it takes on the properties of thermoplastics and thermosets but is still a plastic.

Do you need a quote for manufactured plastics such as PTFE? At Severna, we offer high-quality materials for your needs. You can reach out to us today to get a quote.