With a large inventory of plastics on site and expert machinists on staff, Severna Operations can produce parts with a wide range of diameters and lengths.

With a large inventory of plastics on site and expert machinists on staff, Severna Operations can produce parts with a wide range of diameters and lengths.

When we receive your product design in any format , such as 2D or 3D CAD, we quickly get to work providing an accurate timeline and quote. Many projects can be completed in 4 weeks, but we will expedite when possible to meet your scheduling requirements.

Our plastic CNC turning meets tight tolerances of ±.0005” through the expertise of our operators and our comprehensive inspections post-production.

In addition to our standard plastic CNC turning capabilities, we offer secondary services such as custom tool design, cryogenic and hand deburring, and more.

We continue to improve our services and machines to meet the demands of almost every industry, from automotive to medical.

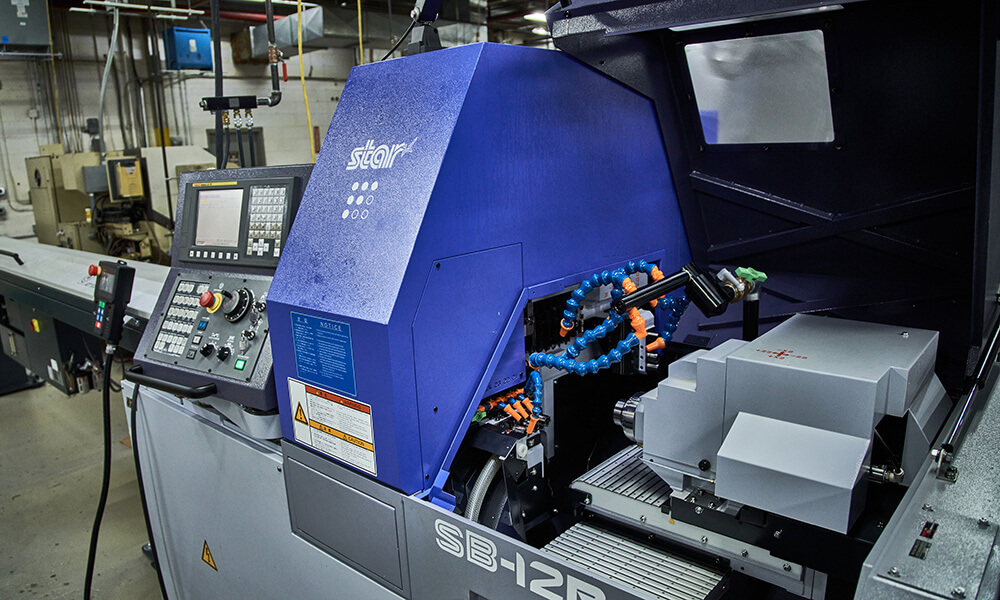

At Severna Operations, we combine efficient machines with expert machine operators for the best quality in precision plastic components. Plastic CNC Turning maintains high precision, quality, and repeatability for quick turnaround where necessary.

Our inventory includes every plastic from ABS to Vespel® with the quality standards to meet your requirements. As an ISO 9001 compliant company, we ensure these components hold up in their end use.

Part Diameter

Max (Chuck Capacity)

8 in

203.2 mm

Max (Bar Feed Capacity)

3 in

76.2mm

Part Length

Max (Bar Feed Capacity)

12 in

304.8 mm

AS 9100 Compliant

ASTM

FDA Compliant

ISO 9001 Certified

Mil-Spec

RoHS Compliant

SAE

Parting/Cutting

Facing

Turning

Contour Turning

Form Turning

Taper Turning

Straight Turning

Threading

External

Internal

Internal Forming

Drilling

Knurling

Boring