Are you looking for a high-performance polymer that is both lightweight and durable? If yes, look no further than Techtron PPS. This advanced engineering breakthrough offers numerous advantages, from its exceptional resistance to wear and heat to its low-temperature flexibility and electrical insulation.

Techtron PPS is becoming increasingly popular. Its superior properties and potential for cost savings make it perfect for many industries. In this article, we’ll discover what Techtron PPS is, how businesses and factories use it, and the advantages of this material.

Techtron PPS was first created in the late 1950s. Scientists invented a new plastic called polyphenylene sulfide (PPS). It was more heat-resistant and durable than other plastics. The scientists used injection molding to make the first Techtron PPS products.

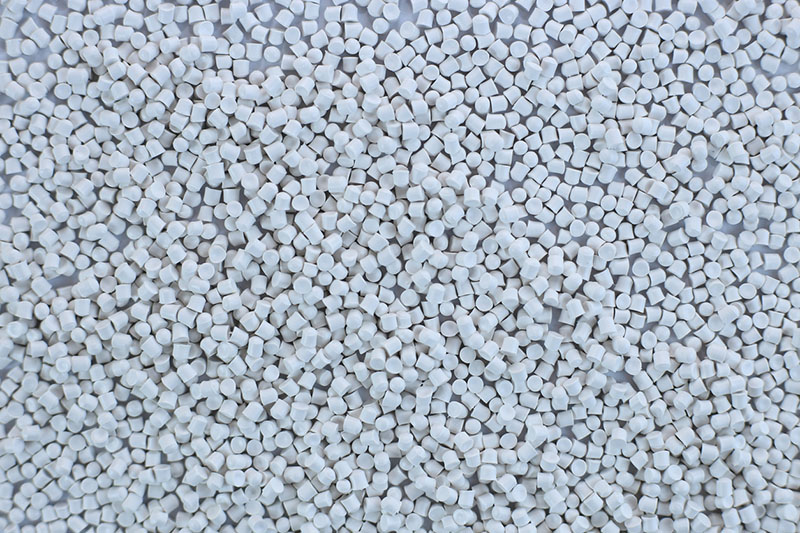

Techtron PPS is a special kind of plastic. It’s strong and offers superb mechanical and chemical properties compared to other engineered plastics.

Techtron PPS has excellent heat and chemical resistance, making it popular in various products and manufacturing processes. It’s also lightweight and beneficial in products where weight is critical.

Techtron PPS offers several benefits. Here are some of the notable advantages:

Techtron PPS is a super-strong material that won’t tear, rip, or stretch. It’s the go-to for parts and components that need to be tough and durable, like car parts, medical equipment, and airplane parts.

Techtron PPS won’t break down when it comes into contact with powerful chemicals like solvents. This makes it perfect for things like cars and factory parts that might come into contact with these harsh substances.

Techtron PPS can withstand high temperatures. So it’s tough enough to work in extreme environments. Typical uses include engines, electrical parts, and industrial components.

Techtron PPS is cheaper than many other plastics, so it’s an economical option for many projects. It works well for food industry components, car parts, and industrial manufacturing.

Techtron PPS has an impressive strength-to-weight ratio. That means it’s much more robust than other plastics and engineering materials while still lightweight. That makes it perfect for things like medical equipment and parts used in aerospace, where weight is essential.

There are many different Techtron PPS products available. Here are some of the types you may find:

These Techtron PPS products can move heat efficiently and quickly. They’re often used as electrical insulators and as part of engine blocks and fuel tanks.

Some Techtron PPS products resist harsh chemicals like oils, acids, and solvents. They’re suitable for parts that touch these chemicals, like seals, gaskets, and tubing.

These types of Techtron PPS products are flame retardants. That means it won’t burn easily and will slow the spread of flames. It’s often used in electrical parts and where fire safety is essential.

Techtron PPS Wear Resistant products are designed to last. It can handle repeated use and won’t wear down quickly, making it perfect for parts that get a lot of use, like gears and bearings.

Techtron PPS is growing in popularity in a wide range of industries. Here are some examples of where it’s used and applied.

Techtron PPS is a robust and long-lasting plastic used to make parts like medical gadgets, cars, and machines. It’s great for turning, drilling, tapping, and milling.

Techtron PPS is an excellent material for making pipes. It’s powerful and can resist chemicals and heat. That means it can create solid and reliable pipes for businesses and factories.

Techtron PPS is used in the electrical industry to keep electricity from flowing in the wrong places. It’s often used to make electronic circuit boards. It has excellent properties that make sure the electricity stays where it should.

Techtron PPS is an excellent material for making gears and bearings. It doesn’t wear down quickly and helps things move without too much friction. You can find it in many machines in factories.

Techtron PPS can be used in structural components. It’s often used to make lightweight parts for the aerospace and car industries.

Techtron PPS is a type of plastic used to make many car parts, such as fuel systems, brake components, and electric insulation. It’s popular because it does a great job keeping its shape when exposed to heat and lasts a long time.

Techtron PPS is perfect for making medical equipment because it is strong and resists chemical damage. It makes parts for drug injection systems, surgical instruments, and testing machines.

Techtron PPS is an excellent choice for parts that get worn out quickly. It’s used to make conveyor belts, blades, and other pieces that experience wear and tear. This material is good at resisting scratches and scuffs.

Techtron PPS is great for heat exchangers because it can withstand high temperatures and helps transfer heat quickly. It’s popular for use in businesses and factories to make heat transfer more efficient.

Techtron PPS has plenty of exciting applications. Whether medical, automotive, or aerospace, the possible uses are endless.

That’s all thanks to its unique qualities, including strength, resistance to heat and chemicals, and cost-effectiveness. As a business, consider the time and money you can save using this product.

Get a quote from our team for more information on this and other high-performance engineering products. As precision engineering experts, we have some of the best industrial materials available.